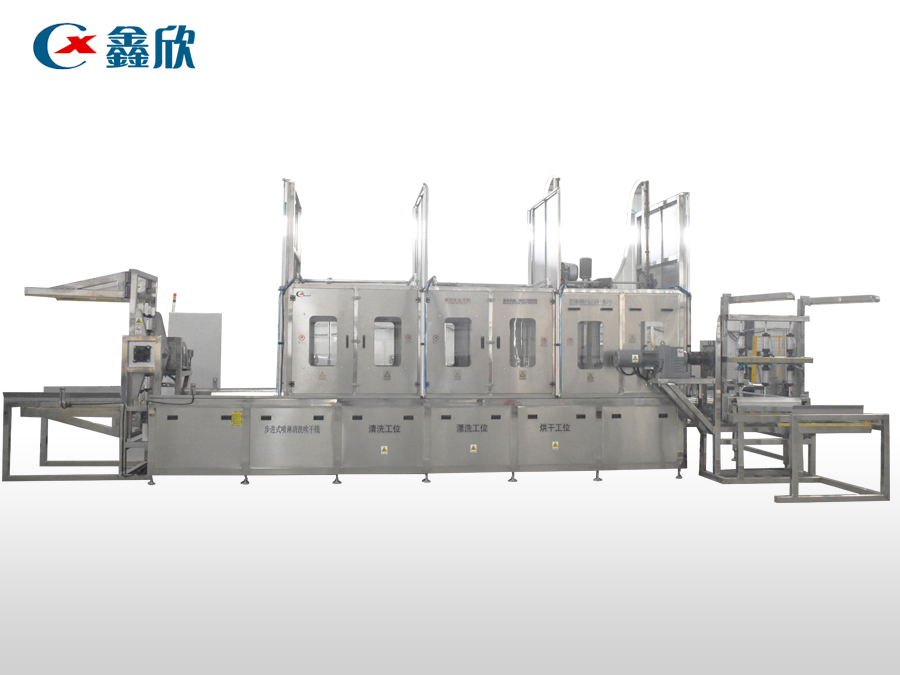

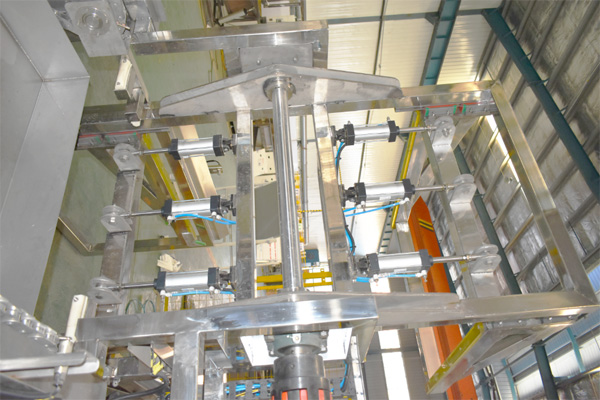

01) Set various parameters for the operation of the equipment through the touch screen on the device. The cleaning bucket is transported to the buffer bracket by the AGV car, and the workpiece is clamped by the clamping device and rotated 180 degrees by the flipping motor, so that the bucket mouth is placed downward at the loading station. The equipment operation device automatically moves the material bucket to the spray coarse washing station. The high-pressure spray coarse washing station is equipped with a rotating nozzle on the inner wall of the bucket to clean the inner wall of the bucket. Top and side nozzles are installed on the outside of the barrel to clean the outer wall of the material barrel. The workstation is equipped with a detector, and the spraying station stops working when the workpiece is in motion. After the material bucket undergoes spray coarse washing, the equipment operation device automatically moves the material bucket to the spray fine washing station. The high-pressure spray fine washing station is equipped with a rotating nozzle on the inner wall of the bucket to clean it. Top and side nozzles are installed on the outside of the barrel to clean the outer wall of the material barrel. The workstation is equipped with a detector, and the spraying station stops working when the workpiece is in motion. After the spray cleaning is completed, the material bucket runs to the high-pressure air cutting and drying station. The hot air drying uses a high-pressure fan and a hot air generator to quickly dry the workpiece. After the workpiece is dried by hot air, it runs to the cutting and flipping station. The workpiece is tightened and flipped by the clamping device. After flipping 180 degrees, the workpiece is placed on the buffer bracket and the AGV car drives the material bucket into the clean bucket temporary storage area.

| Previous:Fire mask ultrasonic cleaning machine | Next:Fire mask ultrasonic cleaning machine |

TEL

TEL

Product

Product

Case

Case

Contact

Contact